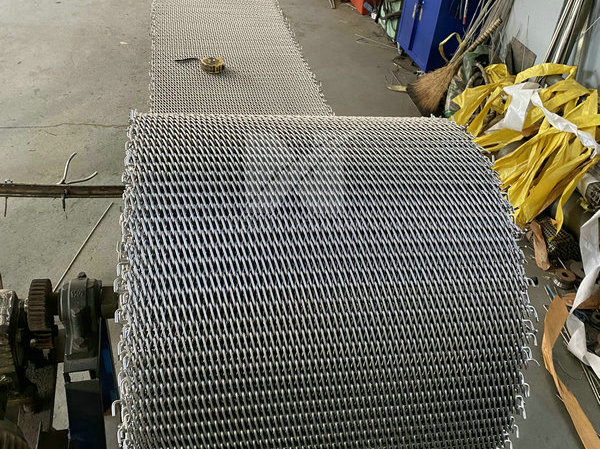

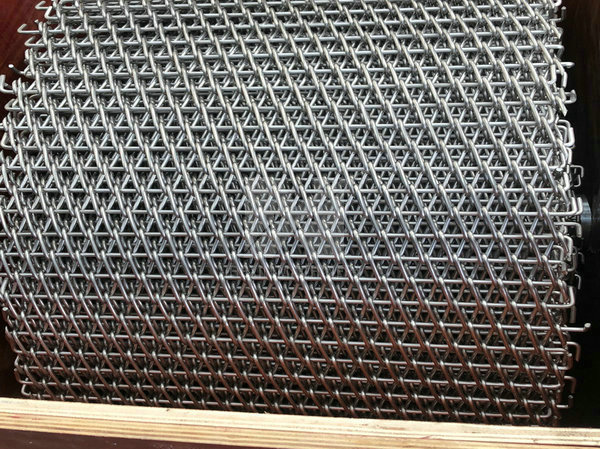

High temperature resistant mesh belt generally refers to mesh belts produced from stainless steel with a temperature resistance of more than 750°C,

mainly using high nickel-chromium alloy materials such as 316 (0Cr17Ni12Mo2), 310S (0Cr25Ni20), 314 (1Cr25Ni20Si2), and 2080 (Cr20Ni80).

Has the following characteristics:

1. High temperature resistance, the high temperature resistant mesh belt has a high percentage of chromium and nickel.

The nickel element has excellent special properties such as energy storage, anti-corrosion, wear resistance, high temperature resistance and high strength,

making the high temperature resistant mesh belt have the best The ability to resist deformation, can work continuously at high temperatures, and has good high temperature resistance.

2. Corrosion resistance: The materials selected for the high temperature resistant mesh belt, chemical solvents, drugs and other chemicals have no effect on these materials,

so that it cannot cause corrosion and other chemical reactions on the high temperature resistant mesh belt at work.

3. Bending fatigue resistance: The high temperature resistant mesh belt has high tensile strength and bending fatigue resistance, and it is not easy to deviate or deform during use.

4. Anti-adhesion: The application scenarios used by the high temperature resistant mesh belt need to be clear and easy to complete with paint, resin, chemical products and other adherends,

and no excess residue will be produced on the mesh belt.

5. Air permeability: The air permeability of the high temperature resistant mesh belt is high, which can avoid excessive heat loss in the furnace, and can save production costs to a certain extent.

The mesh belt is connected by a thicker string shaft, and both sides are inlaid with baffles of the same height, which can bear heavier objects and prevent objects from falling off the mesh belt.

It is mainly used for cleaning and heat treatment of objects.

High-temperature mesh belts mainly include annealing furnace mesh belts, baking furnace mesh belts, electric furnace high temperature resistance, mosaic mesh belts have high heat resistance,

strong corrosion resistance, high tensile strength, small elongation, uniform pitch, and fast heat flow. Energy saving, long service life, etc.

Mainly used for annealing, quenching, hot melting, tempering of glass products, ceramic products and other tunnel kiln conveyor lines, and can also be used for glass bottles and cans,

food, light bulbs, metals, utensils, chemical fiber, electronics, powder metallurgy, heat treatment, etc. The use of automatic devices and automatic assembly lines in various industries is suitable

for the transmission of various kiln systems such as natural gas, coke oven gas and electronic infrared rays.

Main factors affecting life span:

1. Mesh belt material

2. The mesh belt furnace is used for quenching or carburizing, and the carburizing life will be relatively short

3. The quenching medium used, generally the salt bath mesh belt has a shorter service life

4. The design of the equipment itself, the equipment has mechanical problems

High temperature resistant mesh belt generally refers to mesh belts produced from stainless steel with a temperature resistance of more than 750°C, mainly using high nickel-chromium alloy materials

such as 316 (0Cr17Ni12Mo2), 310S (0Cr25Ni20), 314 (1Cr25Ni20Si2), and 2080 (Cr20Ni80).

Has the following characteristics:

1. High temperature resistance, the high temperature resistant mesh belt has a high percentage of chromium and nickel. The nickel element has excellent special properties such as energy storage,

anti-corrosion, wear resistance, high temperature resistance and high strength, making the high temperature resistant mesh belt have the best The ability to resist deformation,

can work continuously at high temperatures, and has good high temperature resistance.

2. Corrosion resistance: The materials selected for the high temperature resistant mesh belt, chemical solvents, drugs and other chemicals have no influence on these materials,

so that it cannot cause corrosion and other chemical reactions on the high temperature resistant mesh belt at work.

3. Bending fatigue resistance: The high temperature resistant mesh belt has high tensile strength and bending fatigue resistance, and it is not easy to deviate or deform during use.

4. Anti-adhesion: The application scenarios used in the high temperature resistant mesh belt need to be clear and easy to complete with paint, resin, chemical products and other adherends,

and no excess residue will be produced on the mesh belt.

5. Air permeability: The air permeability of the high temperature resistant mesh belt is high, which can avoid excessive heat loss in the furnace, and can save production costs to a certain extent.

Typical uses, belt types and material

|

Uses |

Belt Type |

Materials |

|

Sintering |

K2W A2W A4 RRW |

SUH330. AISI314. SUS310S |

|

Brazing |

K2W A2W RR RRW A4 K2 |

SUH330. AISI314. SUS310S |

|

Hardening |

K2W A2W A4 F2 K2 |

SUS310S |

|

Heating |

K2 A4 |

NCHW1. SUS310S |

|

Tempering |

K2W A2W A4 F2 K2 |

SUS304 (SUS410) (SUS430) |

|

Lehr |

K2 k2W KF2 A4 |

SUS304. SUS410 (SUS430) (SWRM) |

Components of typical material

Material |

Chemical Components |

Max.

Operating

Temp. |

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Other |

|

SUH 330 |

≤0.15 |

≤0.50 |

≤2.00 |

≤0.040 |

≤0.030 |

33.00-37.00 |

14.00-17.00 |

|

1150 |

|

AISI 314 |

≤0.25 |

50-3.00 |

≤2.00 |

≤0.045 |

≤0.030 |

19.00-22.00 |

23.00-26.00 |

|

1150 |

|

SUS 310S |

≤0.08 |

≤0.15 |

≤2.00 |

≤0.045 |

≤0.030 |

19.00-22.00 |

24.00-26.00 |

|

1090 |

|

NCHW1 |

≤0.15 |

0.75-1.6 |

≤2.50 |

--- |

-- |

≥77.00 |

19.00-21.00 |

Fe≤1.0 |

1150 |

|

SUS 304 |

≤0.08 |

≤1.00 |

≤2.00 |

≤0.045 |

≤0.030 |

8.00-10.50 |

18.00-20.00 |

|

870 |

|

SUS 410 |

≤0.15 |

≤1.00 |

≤1.00 |

≤0.030 |

≤0.030 |

-- |

11.50-13.50 |

|

700 |

|

SUS 430 |

≤0.12 |

≤0.75 |

≤1.00 |

≤0.030 |

≤0.030 |

-- |

16.00-18.00 |

|

700 |

|

DIN 1.4841 |

≤0.2 |

1.5-2.5 |

≤2.00 |

≤0.030 |

≤0.030 |

19.0-21.00 |

24.0-26.0 |

|

1150

|

HEXIN Machinery produces various OEM wear and corrosion resistant components for the cement, lime, coal, shot blast machines,and iron Ore industries.

The castings HEXIN made generally are made from special irons and manganese steels, which are critically used in the sectiors of cement manufacturing,coal mining (surface and underground), copper smelting,crushers direct reduction of iron (DRI)

Iron ore manufacturing,Lime manufacturing. All the castings manufactured at HEXIN go through strict quality checks at all stages before being supplied to customers.

Contact Us

Tel.: 0086-532-6777 5336

Fax.: 0086-532-8898 7192

skype: zhishuai.liu Email: info@hexinmachinery.com

Office address: Rm 1402-1403, Excellence Bldg, No.128 Yanji Rd, CBD,Shibei Dist, Qingdao, Shangdong 266000, China