Garbage incinerator grate bar

With the rapid development of domestic urbanization, waste incineration, a waste treatment method that can save land resources, harmless, reduce and recycle waste, has become more and more widely used. There are various forms of grate incinerators, and their applications account for more than 80% of the world's total waste incineration market. The grate type incinerator has the advantages of low requirements for waste pretreatment, wide adaptability of waste calorific value, long continuous and stable operation time, and simple operation and maintenance.

The grate sheet is the core component of the grate-type incinerator, which is easy to wear and tear. The stability of the grate sheet plays a decisive role in the continuous and stable operation of the incinerator. Through reasonable structure design and material application of grate slices, we design grate slice products suitable for the thermal properties of domestic waste, reduce the problems of grate slice sticking, abnormal wear and burning loss, and improve the operation stability and reliability of grate type incinerators.

1. Working characteristics of grate pieces

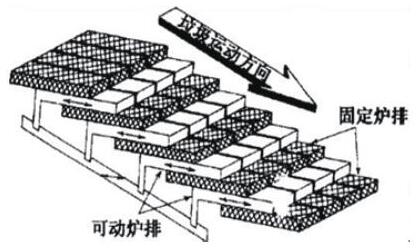

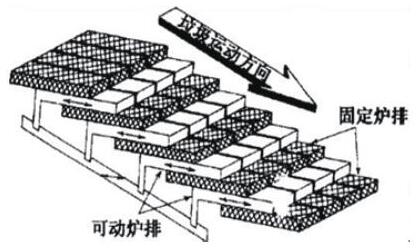

The mechanical grate furnace is composed of mechanical grate pieces to form the hearth, and the relative movement between the movable and fixed grate pieces makes the garbage constantly flip, stir and push forward. The design of the grate pieces for reciprocating incinerators requires regular reciprocating motion of the grate pieces, so as to ensure that the garbage enters the furnace to contact with hot air, heat up, dry, catch fire, and burn embers.

Figure 1 Schematic diagram of the reciprocating grate

The reciprocating motion of the grate not only moves the garbage evenly, but also agitates the garbage, making the garbage mixed with the burned garbage, causing the garbage of the reciprocating grate piece to catch fire at the bottom, and the grate movement can effectively agitate the garbage. The relative movement of the grate and the garbage can loosen the burning garbage, increase the air permeability of the garbage, and improve the combustion conditions.

In order to ensure the continuous and stable combustion of the incinerator, the furnace temperature is maintained at 950 ~ 1050 ℃, and the high temperature oxidation resistance requirements are put forward for the grate; due to the imperfect classification of garbage, the proportion of the garbage entering the furnace is large, and the mechanical load of the grate sheet is large, which has a great impact on the furnace. The grate sheet requires mechanical wear; the garbage usually contains CI, S and other elements due to its complex composition, which forms acid gas after combustion, which has a corrosive effect on the metal material of the grate sheet.

Therefore, the working environment of the grate sheet has the following characteristics: the drying section has a large garbage load and is mainly subjected to mechanical wear; the combustion section has a high ambient temperature and is mainly subjected to high temperature wear; the burning section has many incombustible materials, and solid particles are easily mixed into the grate sheet In the gap between them, it is mainly subjected to abnormal wear such as eccentric wear; in addition, the atmosphere formed after garbage incineration contains high-temperature corrosive gas, which forms a corrosive effect on the grate sheet; The ignition loss rate has a negative impact; if the grate pieces are lifted and burned, if the frequency is too high, the furnace needs to be shut down for maintenance, which will inevitably affect the operation of the incineration plant.