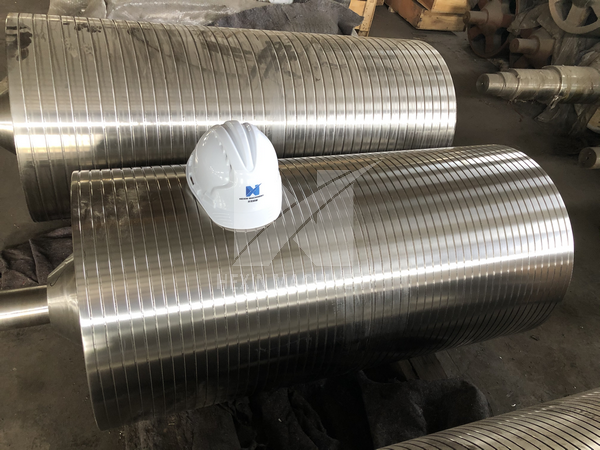

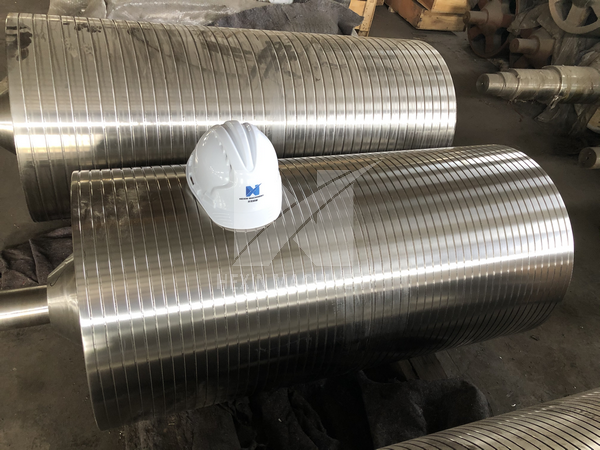

Analysis of Failure Causes of Surfacing Materials for Composite Remanufactured Sink Rolls

The influencing factors and laws of the mechanical properties of surfacing deposited metal were analyzed. Firstly, the reasons for the failure of the surfacing materials for sink rolls are analyzed. It is considered that the surfacing metal has poor strength and plasticity, coarse columnar crystals, high inclusion content and high residual austenite content in the microstructure.

It has a greater impact on surface cracks and spalling of sink rolls. Based on the Cr5 surfacing alloy system, the effects of V and Mo alloy contents on high temperature tensile, thermal fatigue properties, high temperature wear properties, impact toughness and hardness at room temperature were studied by single variable method. Through the analysis of the microstructure of the cladding metal, the relationship between the change of the microstructure and the mechanical properties is discussed, and the finally optimized cladding metal has excellent comprehensive mechanical properties. The optimized V and Mo contents (mass fraction) are 0.5% and 2.4%, respectively.

At the same time, adding an appropriate amount of strong carbide forming elements Ti and RE to the surfacing flux-cored wire for deoxidation, controlling the content of S and P in the surfacing flux-cored wire, and improving the plasticity of the surfacing deposited metal are also the key to avoiding surfacing cracks. In the case of vertical grinding surfacing equipment keeping the content of alloy elements in the surfacing metal unchanged, the addition method of C, Cr and V elements in the surfacing flux-cored wire was changed. Chromium carbide and vanadium carbide are added to the formula of 1# and 11# welding wire respectively, and graphite and micro-carbon ferrochromium or graphite and ferrovanadium are added to the formula of 2# and 22# welding wire respectively.

Through OA, SEM, EDS, XRD, TEM and SAD analysis, it is pointed out that the surfacing metal is composed of lath martensite and retained austenite. There are two types of inclusions in the deposited metal of sink rolls surfacing welding: composite alloy inclusions (higher content of carbon, chromium, vanadium, and molybdenum) and composite deoxidation inclusions (higher content of manganese, silicon, aluminum, rare earth, etc.).

Copyright © 2016

Hexin Machinery All Internet

Sitemap