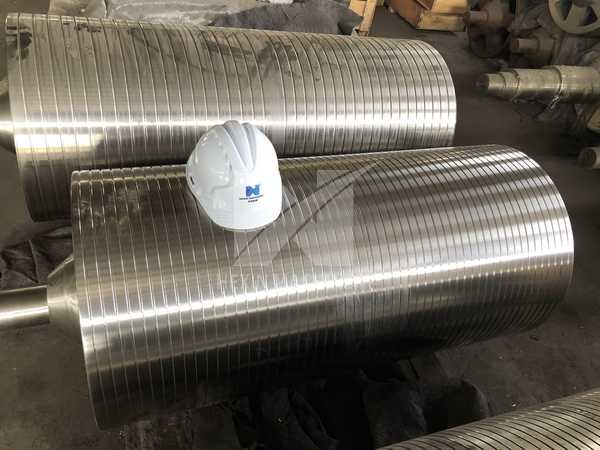

Repair method of polymer composite material for sink rolls bearing wear

The bearing position of sink rolls has super adhesion, excellent compressive strength, wear resistance and corrosion resistance and other comprehensive properties. It adopts Meijiahua-Fushilan 2211F polymer composite material, which can be repaired without disassembly on site when the wear size of the transmission part is relatively small. It not only avoids the machining of sink rolls, but also has no thermal stress of repair welding, and the repair thickness is not limited.

At the same time, the wear resistance of sink rolls products and the concessionality that metal materials do not have, ensure 100% contact fit of the repaired parts, reduce the shock and vibration of the equipment, avoid the possibility of wear, and greatly extend the equipment parts (including bearings) It can save a lot of downtime for enterprises and create huge economic value.

Cold welding repair method: The cold welding machine uses the principle of electric spark high-frequency discharge to perform heatless surfacing welding on the metal surface, so it does not deform, anneal, undercut and residual stress in the process of repairing sink rolls, sand holes, scratches and other defects. , does not change the state of the metal structure. The repairing precision is high, and the coating thickness is from several microns to several millimeters. It can deposit, seal, fill and repair defects such as wear, scratches, pinholes, cracks, defect deformation, hardness reduction, trachoma, damage and other defects in metal workpieces. , It only needs to be polished and polished, and it can also be used for various types of mechanical processing such as turning, milling, planing, and grinding, as well as post-processing such as electroplating.

Copyright © 2016

Hexin Machinery All Internet

Sitemap