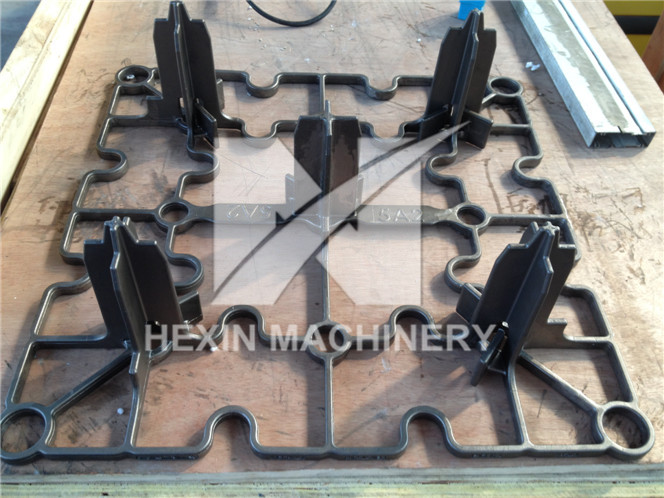

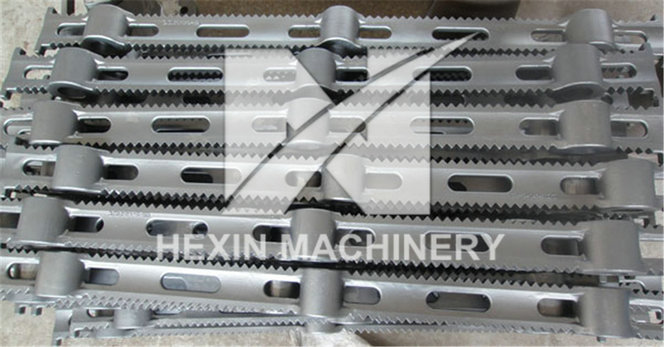

| Item | Lost wax casting stackable grids for pusher furnace |

| Usage | Large inventory of cast tray patterns and designs used in all furnace types and hearth designs such as batch, continuous, pit & box. |

| Shapes | Multiple round, square, rectangular, bolted assemblies and reversible tray designs |

| Specifications | Multiple heat & corrosion resistant alloy compositions available |

| Technology | Chemical analysis by spectrometer for each heat, PT 100%(liquid penetrant test), VI(visual inspect)100%, dimensional check. |

| Material | ZG4Cr25Ni20Si2,ZG4Cr25Ni35NbW,2535W2,2848,ZG4Cr28Ni48W5Si2(2848W5),Co20 etc. |

| Products |

Multy purpose furnace tray Base tray for heat treatment furnace Batch skid trays Cast furnace tray Grids baskets for heat treatment fixtures Investment casting base tray Roller hearth trays Stacking trays Tray Assemblies |